Depending on the task, different measuring principles are suitable. EGE offers sensors for level measurement based on the capacitive principle, with microwaves, optically, conductively or ultrasonically.

The MFP level meter for continuous monitoring of various liquids allow measurement of the fill level in plastic or metal tanks of any size. The devices offer a high measurement precision. They work with numerous liquids such as water, oil or emulsions.

Principle of measurement: The microwaves are “guided” along the rod – and are reflected at the surface of the medium. From this the sensor determines the fill level. No adjustment is necessary for various media.

The devices are made of aluminium and AISI 316 Ti stainless steel and are suitable for ambient temperatures between – 20 and +70 °C. Additional devices are available for monitoring highly corrosive liquids with a coated probe and non-metallic thread.

The fill level meters are available in sizes between 300 and 1200 mm in length. The sensors are equipped with a G3/4 thread and are connected via an M12 plug. The display shows the fill level either in cm or percentage value. You can program additional functions such as a fixed offset value or measuring range.

The microwave level controllers of the MFC and MFK series respond to media contact at the tip of the sensor. They are especially insensitive to soiling and build-up.

The devices of the MFK series are made of stainless steel and PTFE and are equipped with a G1/2 process connection. The sensors have a length of 40 mm. Thanks to their integrated electronics, no downstream amplifier is required. The sensors do not have to be adjusted to different media, and for containers made of plastic material, no earth connection is required.

Users can adjust the sensitivity of the devices of the MFC series using a pushbutton. Thus, the sensors can distinguish between different layers of liquids (e.g. water and oil) in the containers allowing for an easy separation of liquids.

The stainless steel and PTFE microwave sensors can be used for virtually all container types and sensor environments. They are also suited for use with powder or granules. The sensors are available with a length of between 120 mm and 1000 mm thus offering various different installation options.

Talk to our experts for flow and flow sensor technology about your request. Feel free to contact us directly by phone via e-mail or contact form.

Contact usDevices of the series DN monitors pressure levels in pipes and containers. However, the high accuracy of its capacitive ceramic gauge head makes it an effective fill level monitor as well.

It can record fill levels with an accuracy of one centimeter in containers that stand five meters tall. Measurement instruments with a 1000 mbar measurement range have proven to be very useful for these types of applications. When measuring the fill level of water, 10 mbar of pressure corresponds to 10 cm water height.

The instrument displays the pressure value digitally. The fill level measurement is not effected by foam on the liquid's surface. Suspended matter inside the container will not effect the measurement either - as long as the matter does not disturb the pressure distribution in the area surrounding the sensor membrane.

The pressure sensor is a compact device that contains all the measurement and evaluation electronics. It is designed for use with 24 V DC. In addition to many programmable features, it also provides two PNP switch outputs and a 4 to 20 mA current output.

Additionally we offer a model with 2 switching points and a rapid programming feature which can be used, for example, for minimum and maximum detection in a container. A model with one analog output only is also availble.

The operation of these level sensors is based on a dielectric measuring method. All media which are surround the sensors measuring electrode, built into the tip of the probe, change the state of dielectric balance between the measuring electrode and the surrounding space. This disturbance in the balance triggers a switching command inside the device. The balance can be adjusted with a built-in potentiometer so that materials with different bulk densities and correspondingly different dielectric constants can be measured optimally.

Metallic or metal clad vessels should be earthed. In the case of plastic vessels filled with electrically conductive materials, the latter should be earthed. In the case of plastic vessels filled with non-conducting materials, an earthed metal band applied on the outside of the vessel may be used as a counter-electrode.

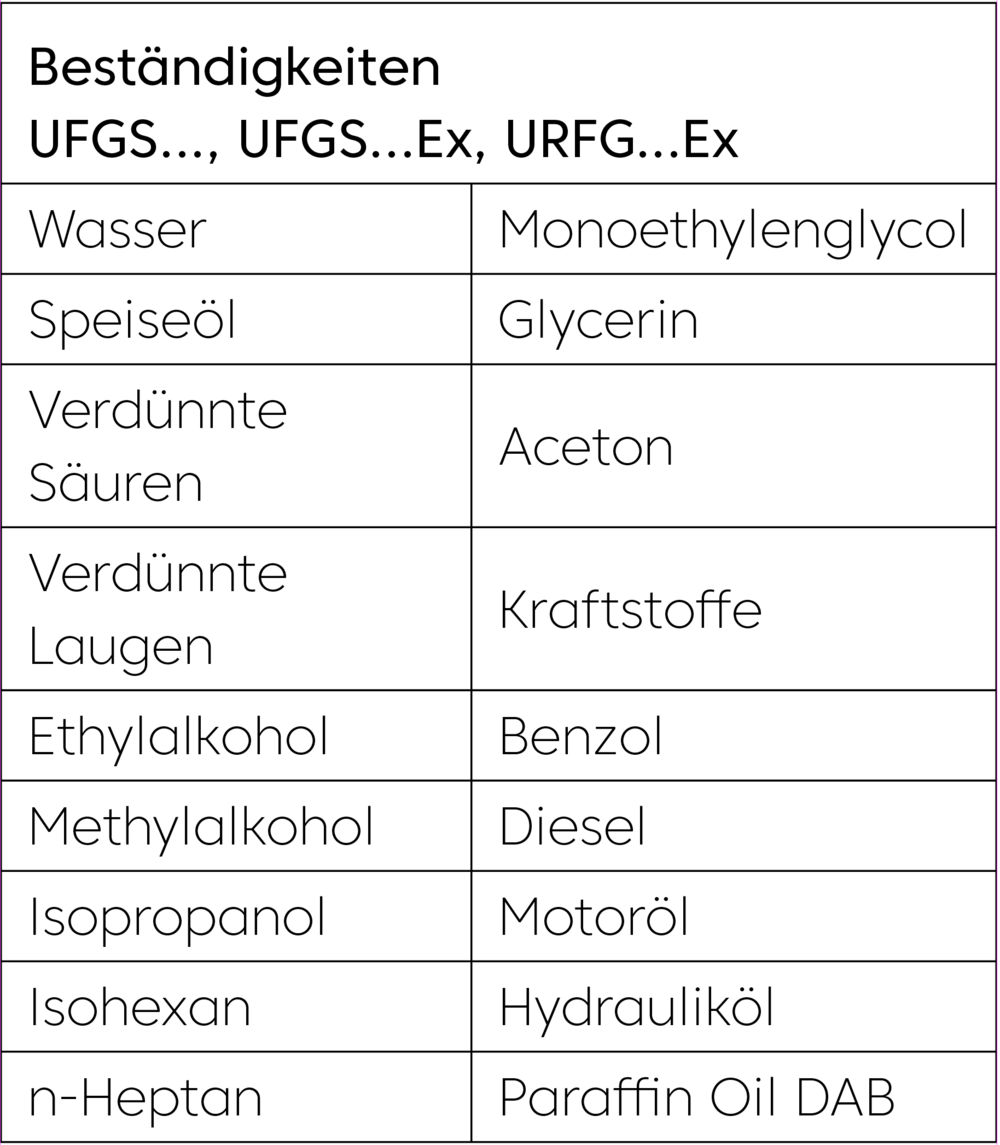

Optical sensors react to a change of the refraction index within the proximity of the sensor tip when being immersed into fluid. The sensor does not have to be adjusted. In rare cases, the container wall or particles within the fluid may reflect the light emitted by the sensor and thus interfere with the fluid detection. A trial run is recommended in such instances. The sensors are designed to be used with the respectively listed fluids under ntormal conditions. The chemical compatibility and technical suitability of the sensor should be tested when used with unlisted fluids.

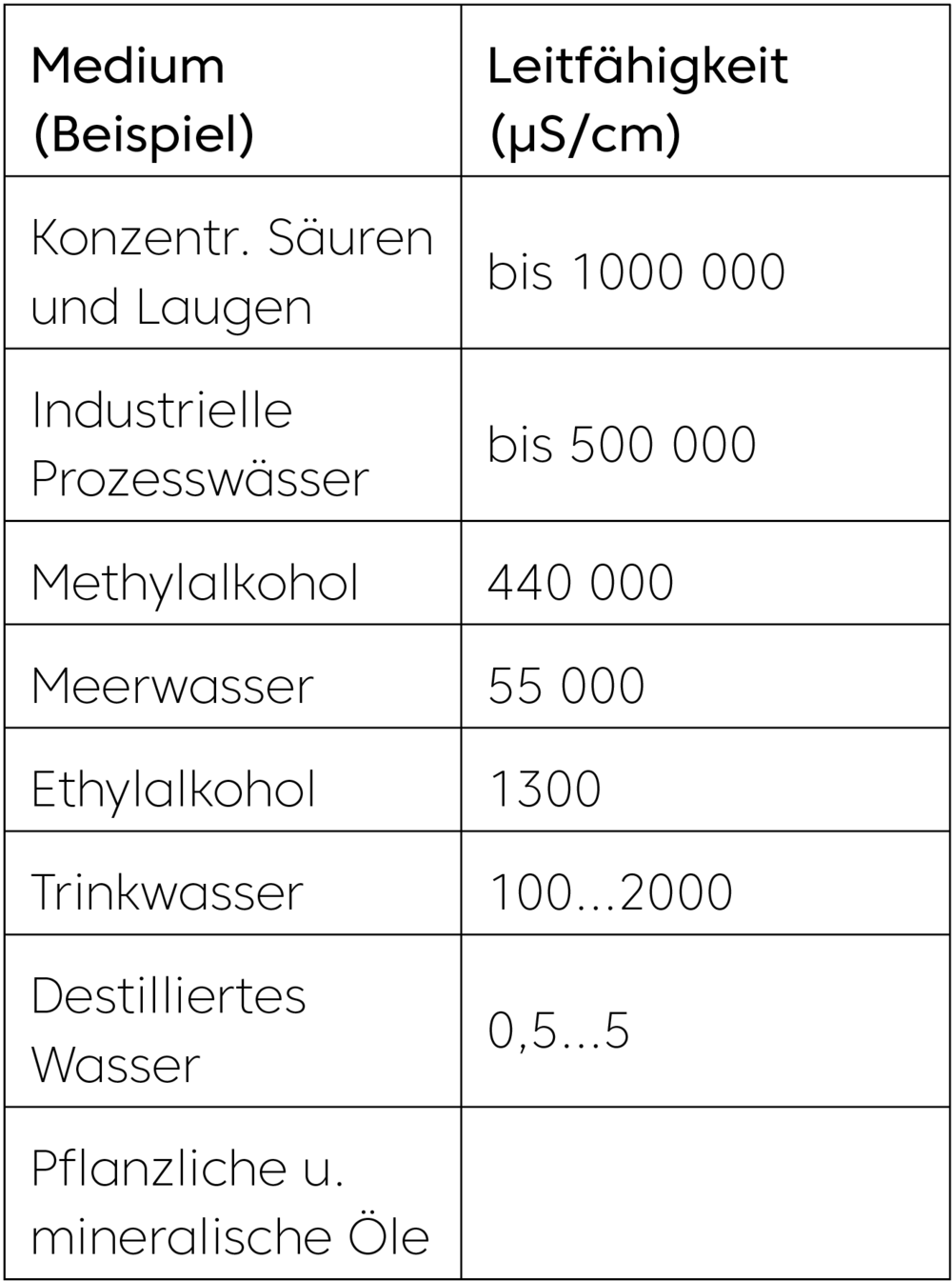

The CFC 050 GSOP enables level detection of fluids with a conductivity >10 µS/cm. Typical applications are dry-running protection or overflow protection in vessel or pipes. The CFC 050 GSOP works with a measuring electrode and a complementary electrode witch is connected to the metallic thread. The switching signal is triggered when the fluid has contact to both electrodes.

Adhesions or splash are no problem. Using the screw-on-electrode the CFC 050 GSOP can even be used in plastic container. The electrodes can easily be shortened by the user.

The hydrostatic fill level sensors of the series DGC 075 are suitable for fill level measuring in liquids and are available for fill levels up to 2000 cm. The measuring range can be adjusted simple and fast by potentiometer and 4 LEDs on the measuring head. It is easy to install with its G3/4 thread, for example in the tank wall, and has protection class IP 67. The sensor has a 4....20 mA signal exit.